+86-15763932413

| Availability: | |

|---|---|

Chifine

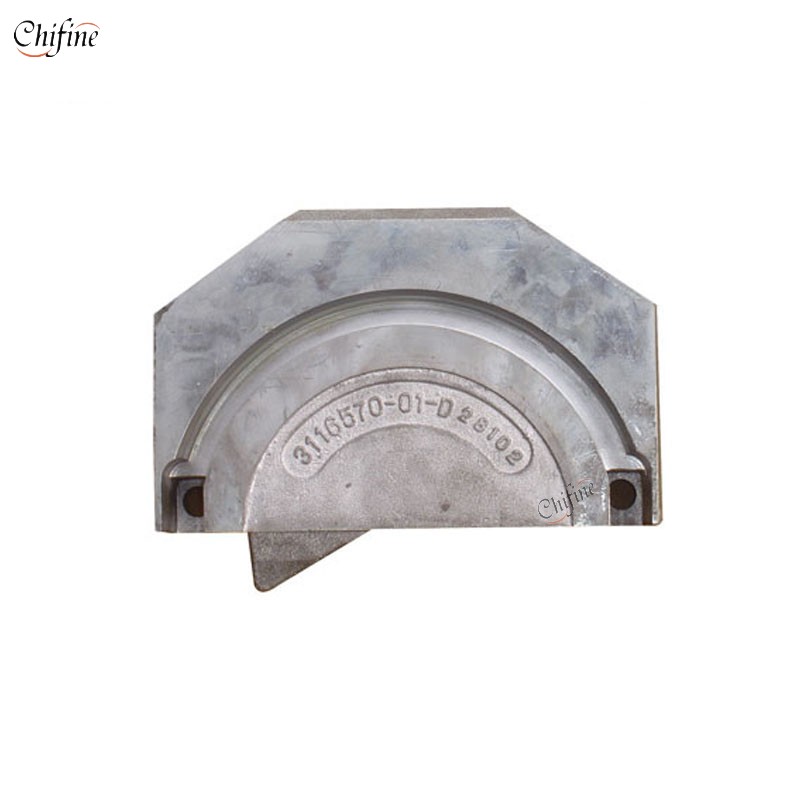

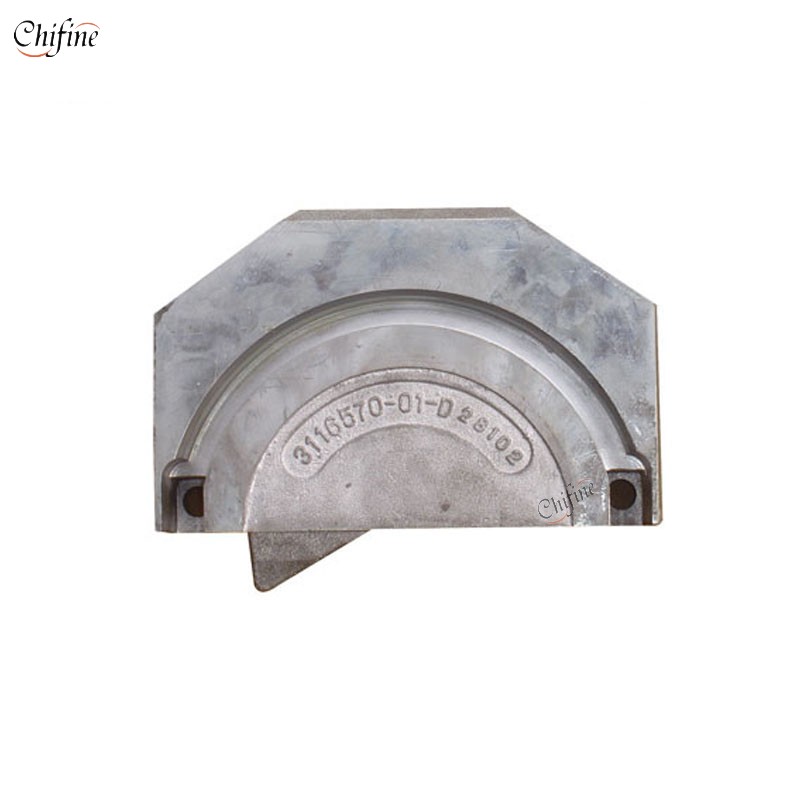

Chifine’s custom precision aluminium sand casting automobile chassis parts are engineered to redefine performance in the automotive, railway, and trailer industries. Leveraging green sand, resin sand, and precoated sand casting processes, these steel automotive chassis components combine lightweight aluminium alloy (A360, A380, ADC12) with exceptional strength, making them ideal for modern vehicle design. With a weight range of 0.03kg to 80kg and a precision tolerance of 0.01mm, our aluminium sand cast auto parts optimize fuel efficiency while ensuring structural integrity. As a factory-direct manufacturer with ISO9001 certification, Chifine delivers tailored automotive chassis casting solutions, supporting OEM/ODM requests and providing one-stop services from casting to surface treatment.

Lightweight & High-Strength: Crafted from premium aluminium alloy (A360, A380, ADC12) to reduce vehicle weight without compromising load-bearing capacity.

Precision Sand Casting: Utilizes green sand, resin sand, and precoated sand processes for intricate designs and tight tolerances (0.01mm).

Versatile Surface Treatment: Offers antirust oil, chrome plating, painting, powder coating, anodizing, and electrophoresis for corrosion resistance and aesthetic appeal.

Integrated Manufacturing: In-house capabilities include casting, CNC machining, polishing, assembly, and plating—streamlining production and reducing costs.

Advanced Quality Testing: Equipped with CMM 3D coordinate measuring machines, ultrasonic testers, and imaging spectrometers to detect defects and ensure compliance.

Customization Expertise: Accepts customer drawings, samples, and design ideas, with engineering support to optimize product structure for casting and performance.

Efficient Production Cycle: Large-capacity facilities and ERP systems enable prompt delivery, even for bulk orders of automobile chassis parts.

Our precision aluminium sand casting components are widely applied in:

Automotive industry: Automobile chassis frames, suspension brackets, engine mounts, and transmission parts for passenger cars, commercial trucks, and electric vehicles.

Railway & trailer sector: Train undercarriage components, trailer chassis fittings, and cargo vehicle structural parts.

Communication equipment: Heavy-duty enclosures and mounting brackets for outdoor telecom devices.

Medical devices: Precision structural parts for diagnostic machines and hospital equipment.

Industrial machinery: Conveyor systems, robotic arms, and manufacturing equipment components.

Parameter | Details |

Material | Aluminium alloy (A360, A380, A390, ADC12, ADC10), zinc alloy (ZA-3, ZA-5, ZA-8) |

Weight Range | 0.03kg - 80kg |

Manufacturing Process | Green sand casting, resin sand casting, precoated sand casting, CNC turning/milling/drilling |

Surface Finish | Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis |

Tolerance | 0.01mm |

Maximum Die Casting Tonnage | 800T |

Testing Equipment | CMM 3D Coordinate Measuring Machine, 2.5D Manual Image Measuring Machine, hardness tester, ultrasonic flaw detector |

Design Software | CAD, PROE, SOLIDWORKS, CAXA UG, CAD/CAM/CAE |

We are a factory-direct manufacturer with our own facility in Qingdao Jimo—an area renowned for its casting and machining industry. This allows us to control quality and offer competitive prices for custom precision aluminium sand casting products.

Yes! Send us your drawings, specifications, or samples, and our team will produce custom samples promptly. We ensure samples match your requirements before full-scale production of automotive chassis casting components.

We offer a wide range of surface finishes, including chrome plating, sandblasting, painting, powder coating, anodizing, electrophoresis, and antirust oil. These treatments enhance corrosion resistance and meet industry-specific aesthetic standards.

We implement a full quality control system, including raw material chemistry analysis, metallographic testing, ultrasonic flaw detection, dimensional inspection, and mechanical property testing. Our factory is ISO9001-accredited by TUV, ensuring consistent quality.

Absolutely! We specialize in OEM and ODM solutions, adapting to customer-specific designs, labels, and performance requirements. Our engineering team can also assist with product optimization and casting simulation for aluminium sand cast auto parts.

Chifine’s custom precision aluminium sand casting automobile chassis parts are engineered to redefine performance in the automotive, railway, and trailer industries. Leveraging green sand, resin sand, and precoated sand casting processes, these steel automotive chassis components combine lightweight aluminium alloy (A360, A380, ADC12) with exceptional strength, making them ideal for modern vehicle design. With a weight range of 0.03kg to 80kg and a precision tolerance of 0.01mm, our aluminium sand cast auto parts optimize fuel efficiency while ensuring structural integrity. As a factory-direct manufacturer with ISO9001 certification, Chifine delivers tailored automotive chassis casting solutions, supporting OEM/ODM requests and providing one-stop services from casting to surface treatment.

Lightweight & High-Strength: Crafted from premium aluminium alloy (A360, A380, ADC12) to reduce vehicle weight without compromising load-bearing capacity.

Precision Sand Casting: Utilizes green sand, resin sand, and precoated sand processes for intricate designs and tight tolerances (0.01mm).

Versatile Surface Treatment: Offers antirust oil, chrome plating, painting, powder coating, anodizing, and electrophoresis for corrosion resistance and aesthetic appeal.

Integrated Manufacturing: In-house capabilities include casting, CNC machining, polishing, assembly, and plating—streamlining production and reducing costs.

Advanced Quality Testing: Equipped with CMM 3D coordinate measuring machines, ultrasonic testers, and imaging spectrometers to detect defects and ensure compliance.

Customization Expertise: Accepts customer drawings, samples, and design ideas, with engineering support to optimize product structure for casting and performance.

Efficient Production Cycle: Large-capacity facilities and ERP systems enable prompt delivery, even for bulk orders of automobile chassis parts.

Our precision aluminium sand casting components are widely applied in:

Automotive industry: Automobile chassis frames, suspension brackets, engine mounts, and transmission parts for passenger cars, commercial trucks, and electric vehicles.

Railway & trailer sector: Train undercarriage components, trailer chassis fittings, and cargo vehicle structural parts.

Communication equipment: Heavy-duty enclosures and mounting brackets for outdoor telecom devices.

Medical devices: Precision structural parts for diagnostic machines and hospital equipment.

Industrial machinery: Conveyor systems, robotic arms, and manufacturing equipment components.

Parameter | Details |

Material | Aluminium alloy (A360, A380, A390, ADC12, ADC10), zinc alloy (ZA-3, ZA-5, ZA-8) |

Weight Range | 0.03kg - 80kg |

Manufacturing Process | Green sand casting, resin sand casting, precoated sand casting, CNC turning/milling/drilling |

Surface Finish | Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis |

Tolerance | 0.01mm |

Maximum Die Casting Tonnage | 800T |

Testing Equipment | CMM 3D Coordinate Measuring Machine, 2.5D Manual Image Measuring Machine, hardness tester, ultrasonic flaw detector |

Design Software | CAD, PROE, SOLIDWORKS, CAXA UG, CAD/CAM/CAE |

We are a factory-direct manufacturer with our own facility in Qingdao Jimo—an area renowned for its casting and machining industry. This allows us to control quality and offer competitive prices for custom precision aluminium sand casting products.

Yes! Send us your drawings, specifications, or samples, and our team will produce custom samples promptly. We ensure samples match your requirements before full-scale production of automotive chassis casting components.

We offer a wide range of surface finishes, including chrome plating, sandblasting, painting, powder coating, anodizing, electrophoresis, and antirust oil. These treatments enhance corrosion resistance and meet industry-specific aesthetic standards.

We implement a full quality control system, including raw material chemistry analysis, metallographic testing, ultrasonic flaw detection, dimensional inspection, and mechanical property testing. Our factory is ISO9001-accredited by TUV, ensuring consistent quality.

Absolutely! We specialize in OEM and ODM solutions, adapting to customer-specific designs, labels, and performance requirements. Our engineering team can also assist with product optimization and casting simulation for aluminium sand cast auto parts.