+86-15763932413

| Availability: | |

|---|---|

Chifine

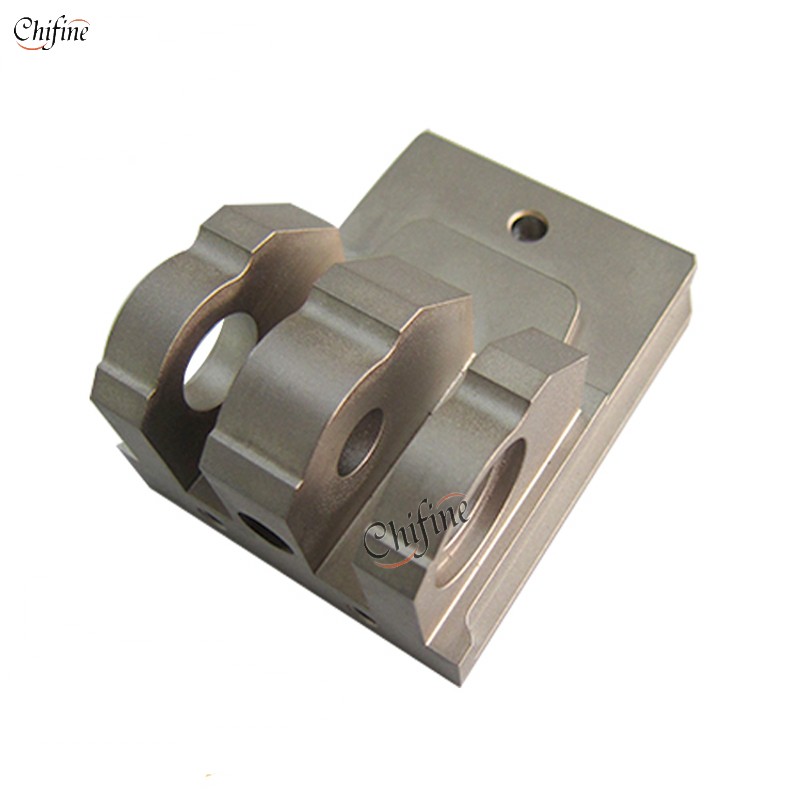

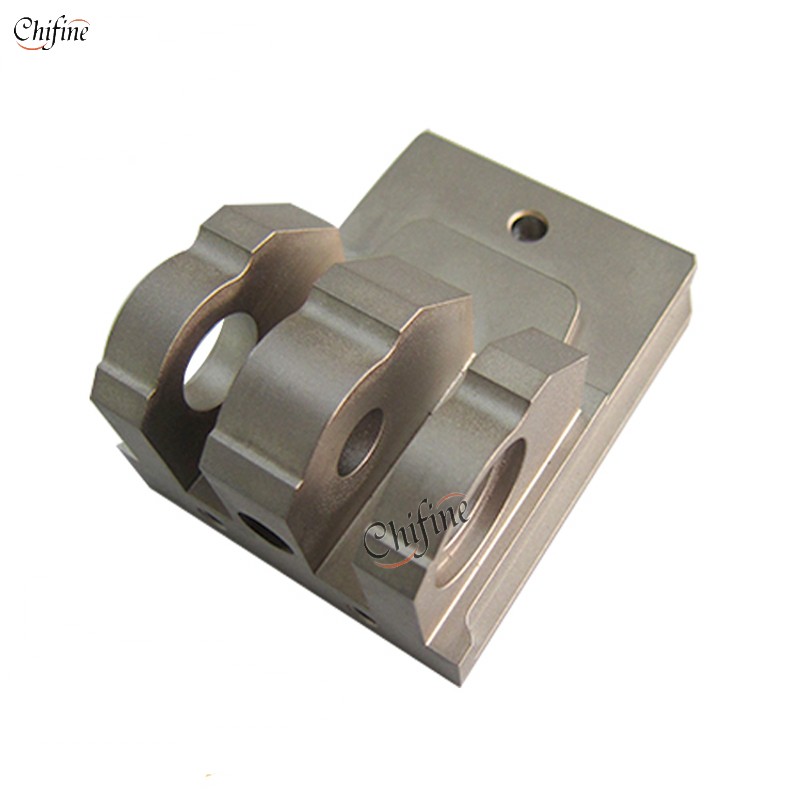

Cast iron traction parts are core agricultural machinery components designed for reliable power transmission and load-bearing in harsh farming environments. As specialized lawn mower traction parts, they integrate the durability of cast iron casting with precision machining to ensure consistent performance in agricultural operations. Qingdao Chifine Machinery, a leading manufacturer with over 10 years of experience in metal casting products, crafts these parts through advanced sand casting processes—including coated sand casting and green resin sand casting—meeting global standards like ISO, DIN, and ANSI. Whether for large-scale farming equipment or residential lawn mowers, these casting iron traction components deliver exceptional stability, corrosion resistance, and wear resistance, making them indispensable for modern agricultural machinery.

Premium cast iron materials: Available in grey iron, malleable iron, and ductile iron, selected for high tensile strength and impact resistance.

Precision CNC machining: Combined with lathe and milling processes to achieve CT6-CT9 casting accuracy, ensuring perfect fit with machinery assemblies.

Comprehensive surface treatments: Options include painting, zinc plating, powder coating, and shot blasting, enhancing rust prevention and aesthetic appeal.

100% quality inspection: Rigorous pre-production and in-process checks using CMM, 2D projectors, and surface roughness testers guarantee defect-free output.

Versatile production capacity: Monthly supply of 1500 tons, supporting both large bulk orders and small-batch customization.

OEM service flexibility: Customized designs based on client drawings or specifications, adapting to diverse agricultural machinery models.

Durable construction: Engineered to withstand heavy loads, frequent use, and extreme weather conditions in farm and outdoor settings.

Global certification: Compliant with ISO9001 and SGS standards, ensuring reliability for international markets.

Tractors, combines, harvesters, and tillers: Provide traction and power transfer for field operations, ensuring stable performance in farmland.

Residential and commercial lawn mowers: Ensure smooth movement and consistent cutting performance, adapting to different lawn sizes.

Construction machinery: Small load-bearing components for excavators, loaders, and graders operating in rugged environments.

Industrial equipment: Hardware fittings, valves, and hydraulic system parts requiring high durability and precision.

Parameter | Details |

Material | Grey iron castings, malleable iron castings, ductile iron castings |

Manufacturing Process | Sand casting (coated sand, green resin sand), CNC machining, lathe, milling |

Weight Range | 1KG - 2TON |

Tolerance Grade | CT6-CT9, compliant with ISO, DIN, ANSI, BS, JIS, GB standards |

Parameter | Details |

Surface Finish | Polishing, shot blasting, painting, zinc plating, powder coating |

Measurement Tools | CMM, 2D projector, caliper, surface rough tester, customized gauge |

Package | Pallet, wooden case, or custom packaging as per client requirements |

Certification | ISO9001, SGS |

Yes, we accept small orders to meet your specific needs, with no minimum order quantity restrictions for most standard and customized designs.

Production lead time varies by order size and complexity, typically 2-4 weeks for small batches and 4-8 weeks for large orders. We prioritize efficient production while maintaining strict quality control.

Absolutely. Our surface treatments (zinc plating, powder coating, painting) and high-quality cast iron materials provide excellent corrosion resistance, suitable for outdoor and humid agricultural environments.

A4: Yes, our professional engineering team offers full R&D and technical support, including drawing design, material selection, and process optimization to bring your custom ideas to life.

A5: Our cast iron traction parts are exported to Eastern Europe, Western Europe, North America, Central America, Asia, Australia, and Mid Africa, adhering to regional quality and safety standards.

Cast iron traction parts are core agricultural machinery components designed for reliable power transmission and load-bearing in harsh farming environments. As specialized lawn mower traction parts, they integrate the durability of cast iron casting with precision machining to ensure consistent performance in agricultural operations. Qingdao Chifine Machinery, a leading manufacturer with over 10 years of experience in metal casting products, crafts these parts through advanced sand casting processes—including coated sand casting and green resin sand casting—meeting global standards like ISO, DIN, and ANSI. Whether for large-scale farming equipment or residential lawn mowers, these casting iron traction components deliver exceptional stability, corrosion resistance, and wear resistance, making them indispensable for modern agricultural machinery.

Premium cast iron materials: Available in grey iron, malleable iron, and ductile iron, selected for high tensile strength and impact resistance.

Precision CNC machining: Combined with lathe and milling processes to achieve CT6-CT9 casting accuracy, ensuring perfect fit with machinery assemblies.

Comprehensive surface treatments: Options include painting, zinc plating, powder coating, and shot blasting, enhancing rust prevention and aesthetic appeal.

100% quality inspection: Rigorous pre-production and in-process checks using CMM, 2D projectors, and surface roughness testers guarantee defect-free output.

Versatile production capacity: Monthly supply of 1500 tons, supporting both large bulk orders and small-batch customization.

OEM service flexibility: Customized designs based on client drawings or specifications, adapting to diverse agricultural machinery models.

Durable construction: Engineered to withstand heavy loads, frequent use, and extreme weather conditions in farm and outdoor settings.

Global certification: Compliant with ISO9001 and SGS standards, ensuring reliability for international markets.

Tractors, combines, harvesters, and tillers: Provide traction and power transfer for field operations, ensuring stable performance in farmland.

Residential and commercial lawn mowers: Ensure smooth movement and consistent cutting performance, adapting to different lawn sizes.

Construction machinery: Small load-bearing components for excavators, loaders, and graders operating in rugged environments.

Industrial equipment: Hardware fittings, valves, and hydraulic system parts requiring high durability and precision.

Parameter | Details |

Material | Grey iron castings, malleable iron castings, ductile iron castings |

Manufacturing Process | Sand casting (coated sand, green resin sand), CNC machining, lathe, milling |

Weight Range | 1KG - 2TON |

Tolerance Grade | CT6-CT9, compliant with ISO, DIN, ANSI, BS, JIS, GB standards |

Parameter | Details |

Surface Finish | Polishing, shot blasting, painting, zinc plating, powder coating |

Measurement Tools | CMM, 2D projector, caliper, surface rough tester, customized gauge |

Package | Pallet, wooden case, or custom packaging as per client requirements |

Certification | ISO9001, SGS |

Yes, we accept small orders to meet your specific needs, with no minimum order quantity restrictions for most standard and customized designs.

Production lead time varies by order size and complexity, typically 2-4 weeks for small batches and 4-8 weeks for large orders. We prioritize efficient production while maintaining strict quality control.

Absolutely. Our surface treatments (zinc plating, powder coating, painting) and high-quality cast iron materials provide excellent corrosion resistance, suitable for outdoor and humid agricultural environments.

A4: Yes, our professional engineering team offers full R&D and technical support, including drawing design, material selection, and process optimization to bring your custom ideas to life.

A5: Our cast iron traction parts are exported to Eastern Europe, Western Europe, North America, Central America, Asia, Australia, and Mid Africa, adhering to regional quality and safety standards.