+86-15763932413

Views: 0 Author: Site Editor Publish Time: 2025-11-20 Origin: Site

Lost-wax casting is an ancient method known for its precision in creating detailed metal objects. From jewelry to aerospace, this technique is highly valued across industries. In this article, we’ll explore the various mediums—like metals, alloys, and even glass—that utilize the lost-wax casting process. You’ll learn which materials are best suited for this method and how they enhance your production process.

Lost-wax casting, also known as investment casting, is a technique in which a model made of wax is covered in a ceramic shell. After the shell hardens, the wax is melted away, and molten metal is poured into the cavity to create a detailed, durable part. This technique has been used for over 6,000 years, with its origins traced back to ancient civilizations like the Egyptians and the Chinese. It has evolved significantly over the centuries, with modern advancements in technology making it even more versatile and precise.

The lost-wax casting process involves several critical steps:

Model Creation: A model of the object is made from wax.

Mold Formation: The wax model is coated with a ceramic slurry, which hardens to form a mold.

Wax Removal: The mold is heated to remove the wax, leaving a cavity in the shape of the object.

Metal Pouring: Molten metal is poured into the cavity to create the final object.

Cooling and Finishing: The cast piece is cooled, and any imperfections are removed through finishing techniques like sanding and polishing.

This process allows for the creation of parts with highly complex shapes and fine details that would be impossible or impractical to achieve with other methods, such as sand casting or die casting.

In recent years, technology has played a crucial role in enhancing lost-wax casting. 3D printing and computer-aided design (CAD) now allow for the creation of highly intricate models with greater speed and accuracy. This has broadened the range of applications for lost-wax casting, particularly in industries that require precision engineering, such as aerospace, medical devices, and automotive manufacturing.

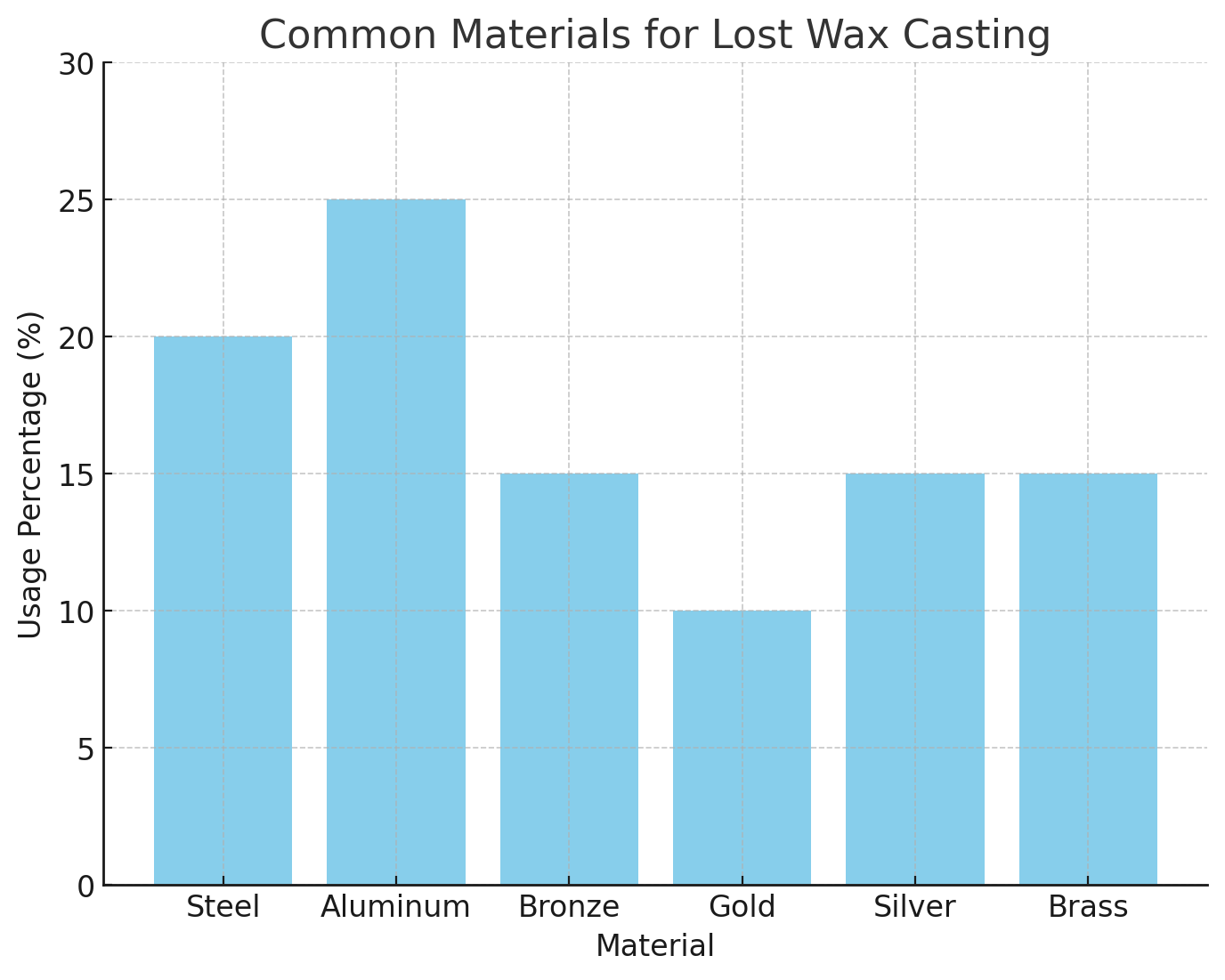

Lost-wax casting is particularly well-suited for metals that require precision and fine details. Metals commonly used in the process include:

● Steel: Stainless steel and carbon steel are frequently used in lost-wax casting, especially for parts requiring strength and durability. Steel castings are used in industries ranging from automotive to energy production.

● Aluminum: Aluminum is often used for casting parts that need to be lightweight and corrosion-resistant. It is a popular choice for both industrial and aerospace applications.

● Bronze: This alloy is known for its corrosion resistance and is commonly used for artistic sculptures, statues, and mechanical parts.

These metals are ideal for lost-wax casting due to their ability to hold intricate details and form parts that require minimal post-processing.

Material Type | Examples | Applications |

Metals | Steel, Aluminum, Bronze | Automotive parts, Aerospace components |

Precious Metals | Gold, Silver, Platinum | Jewelry, Fine art |

Non-Metallic | Glass | Art, Sculptures |

Alloys | Brass, Titanium | Industrial, Aerospace parts |

The lost-wax casting method is a cornerstone of the jewelry industry. It allows jewelers to create highly detailed and intricate designs that would be difficult to achieve using other methods. Common precious metals used in lost-wax casting include:

● Gold: Both yellow and white gold are frequently cast using this method. The ability to create complex designs makes lost-wax casting a favorite among jewelers.

● Silver: Silver casting is used for rings, pendants, and other items, offering a more affordable yet still highly detailed option.

● Platinum: Platinum’s strength and rarity make it ideal for high-end jewelry, where precision and luxury are paramount.

Lost-wax casting allows jewelers to produce unique, high-quality pieces with ease, making it the go-to method for custom jewelry creation.

While lost-wax casting is most commonly associated with metals, it can also be used to create glass objects. Glass casting, particularly in artistic and decorative applications, utilizes the same principles as metal casting, but with some key differences:

● Wax Model: Instead of using a metal model, a wax or resin pattern is used for the glass mold.

● Heat and Precision: Glass casting requires precise control of temperatures to prevent cracking or deforming during the cooling process.

This application of lost-wax casting is widely used for creating sculptures, artistic glassware, and even certain types of industrial components, making it a versatile technique beyond just metal casting.

The versatility of lost-wax casting extends to a variety of alloys, each offering unique properties suitable for different applications:

● Brass: Often used in plumbing fixtures and musical instruments, brass is a popular alloy for casting due to its durability and attractive appearance.

● Titanium: This metal is known for its strength, lightweight nature, and resistance to corrosion. It's ideal for casting in medical devices and aerospace components where performance is critical.

Alloys like these are often chosen for their specific mechanical properties, which make them ideal for lost-wax casting in industries that require high-performance materials.

Lost-wax casting is most commonly used in the jewelry industry to create detailed and customized pieces. It’s also a favored method for producing sculptures and art pieces. This process allows artists to create intricate designs and replicate fine details with precision, making it ideal for high-end and custom creations.

Industries like aerospace and automotive manufacturing rely on lost-wax casting for producing highly specialized parts. The precision of this method ensures that components like turbine blades, engine parts, and transmission components meet exacting specifications. The ability to cast complex geometries makes it a popular choice for parts that need to withstand high stress and extreme temperatures.

Lost-wax casting is widely used in the medical field for creating surgical implants, dental crowns, and precision medical devices. The method’s ability to create highly detailed parts that fit precisely to individual specifications is crucial in these applications, where safety and accuracy are paramount.

Industry | Common Applications | Ideal Materials |

Jewelry | Rings, Necklaces, Earrings, Cufflinks | Gold, Silver, Platinum |

Aerospace | Engine components, Turbine blades, Structural parts | Titanium, Aluminum, Steel |

Medical | Surgical implants, Dental crowns, Medical devices | Stainless Steel, Titanium |

Automotive | Engine parts, Transmission components | Aluminum, Steel |

Lost-wax casting is unmatched in its ability to create intricate and detailed parts. The wax model can capture even the finest features of a design, allowing for the production of highly detailed components that other casting methods cannot replicate.

The use of metals like steel, aluminum, and titanium in lost-wax casting results in parts that are both strong and durable. These materials offer the necessary toughness for industries that require components to withstand high stress, extreme temperatures, and corrosive environments.

While lost-wax casting may have higher initial costs compared to other methods, it is often more cost-effective for small to medium production runs. The ability to create precise parts without the need for extensive machining or additional finishing processes makes it a cost-efficient choice for industries that require high-quality, custom parts.

Unlike sand casting, which uses a sand-based mold, lost-wax casting uses a wax model that is replaced by molten metal. This allows for higher precision and more complex designs. While sand casting is more suitable for large, simple parts, lost-wax casting excels in creating intricate shapes with fine details.

Investment casting (lost-wax casting) offers more flexibility and precision than die casting. Die casting is typically used for high-volume production runs, but it is limited in terms of the complexity of the parts it can create. Investment casting, on the other hand, allows for greater design freedom, particularly when working with intricate geometries.

While 3D printing can create parts directly from digital designs, lost-wax casting provides a more durable and higher-quality finish. The surface finish of lost-wax cast components often requires less post-processing compared to 3D printed parts, making it the preferred choice for industries requiring precise, high-strength parts.

Feature | Lost Wax Casting | Sand Casting | Die Casting |

Precision | High | Low to Moderate | Moderate to High |

Complexity of Shapes | Very High | Low | Moderate |

Material Types | Metals, Alloys, Glass | Primarily Metals | Metals |

Production Volume | Small to Medium Runs | Medium to Large Runs | Large Runs |

When selecting a medium for lost-wax casting, consider factors such as:

● Durability: What level of strength and resistance to wear and corrosion is required?

● Cost: Is the material cost-effective for the production run?

● Application: What industry will the part be used in (e.g., aerospace, medical, jewelry)?

For intricate jewelry and art, precious metals like gold, silver, and platinum are ideal. These materials not only offer aesthetic appeal but also ensure longevity and durability.

For aerospace and industrial applications, metals like steel, titanium, and aluminum are best suited. These materials provide the necessary strength and heat resistance required for high-performance parts.

Lost-wax casting is a time-tested method known for its precision and versatility. It can be applied to a wide range of metals, alloys, and even glass. Industries like jewelry, aerospace, medical, and automotive benefit from its high precision, durability, and flexibility. By choosing the right materials for lost-wax casting, businesses can optimize production and achieve superior quality. Companies like Qingdao Chifine Machinery Co., Ltd. offer reliable solutions for industries, ensuring efficient and high-quality casting processes.

A: Lost Wax Casting is a precision method used to create detailed metal objects. It is commonly used with metals like aluminum, steel, and bronze, as well as non-metallic materials such as glass.

A: Yes, aluminum casting is often performed using the Lost Wax Casting method due to its excellent fluidity and strength after heat treatment, making it ideal for complex shapes.

A: Lost Wax Casting allows for intricate details and fine finishes, making it ideal for creating detailed jewelry pieces in precious metals like gold, silver, and platinum.

A: While Lost Wax Casting is perfect for intricate designs, Aluminum Casting is used for larger, high-strength parts. Both methods offer precision but differ in their applications and scale.

A: Lost Wax Casting is widely used in jewelry, aerospace, automotive, and medical industries for producing high-precision parts and components.